The product description

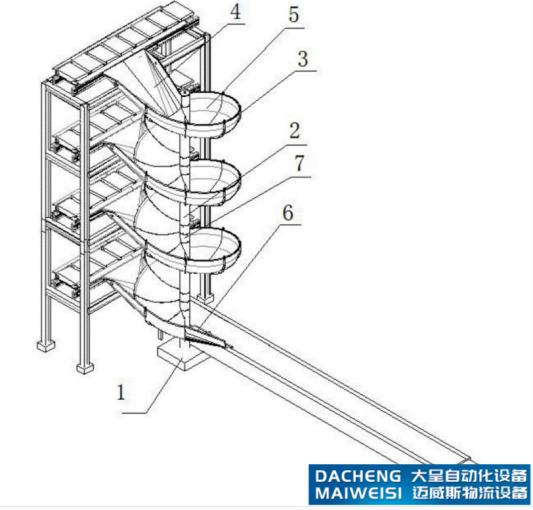

Spiral chute equipment refers to a kind of spiral groove conveying and storage device which is at a certain Angle with the horizontal plane to realize the sliding of all kinds of materials by the weight of the object. It is widely used in express delivery and mail processing centers to realize the accumulation and sliding of large and small packages from top to bottom through the spiral chute without order and rules. There are two common forms of straight chute and spiral chute. Straight-line chute has simple structure, low construction cost, but it takes up large space span, and the speed of mail materials on the chute will be faster and faster with the increase of sliding distance. The spiral chute takes up a small space span, which changes the long-distance slide of the material from the making point to the low point into vertical slide transmission by using the principle of the spiral distance. And after the initial acceleration of the mail, no matter how far the slide is, the speed can basically remain unchanged.

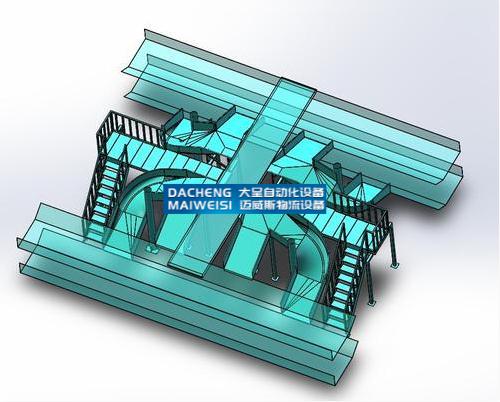

Spiral chute is made of 3mm steel sheet metal after a certain process to form a groove sheet metal assembly, the structure of the sheet metal process structure, long resistance of the equipment, low cost, its strong promotion in high-speed sorting demand in the postal processing center, express sorting center. Common combination forms can be: large rear loading spiral chute, one point two matrix sorting chute, one point four matrix chute.

In addition to being widely used in the express sorting industry, it is also widely used in the delivery of woven bag materials in the flour, chemical industry and rice industry because of the advantages of low cost, high strength of equipment structure, no need for power energy and other aspects.

Product features

Spiral chute covers a small space, feeding can be irregular and no size limit;

The installation position is limited by space and the design layout is flexible and diversified.

One installation, no equipment failure rate and no after-sales maintenance;

Product parameters

Maximum conveying speed | Gravitational acceleration |

Load (dynamic) | 200KG/M |

Delivery carrier | Metal sheet metal |

The standard width | 500-1300 - mm/custom type |

Drive traction | Unpowered free slide |

Maximum traction stroke height | 9m/ power unit |

Machine side guard plate quality | Optional stainless steel/carbon steel spray |

For the material | Woven bags, cartons, Xinfeng, express parcels and other breakage resistant parts. |

Layout handedness | See the selection parameter table |

Transmission channel | Single channel |

Import and export quantity | In the same vertical space can be real single into single out/more into more out, one machine multi-purpose |

If you need us to provide you with technical support services or purchase our equipment, you can obtain the information you need through the following contact information:

v Tel:021-57805016/18717947953 Fax:021-57801828 E-mail:sh_dacheng@163.com