description

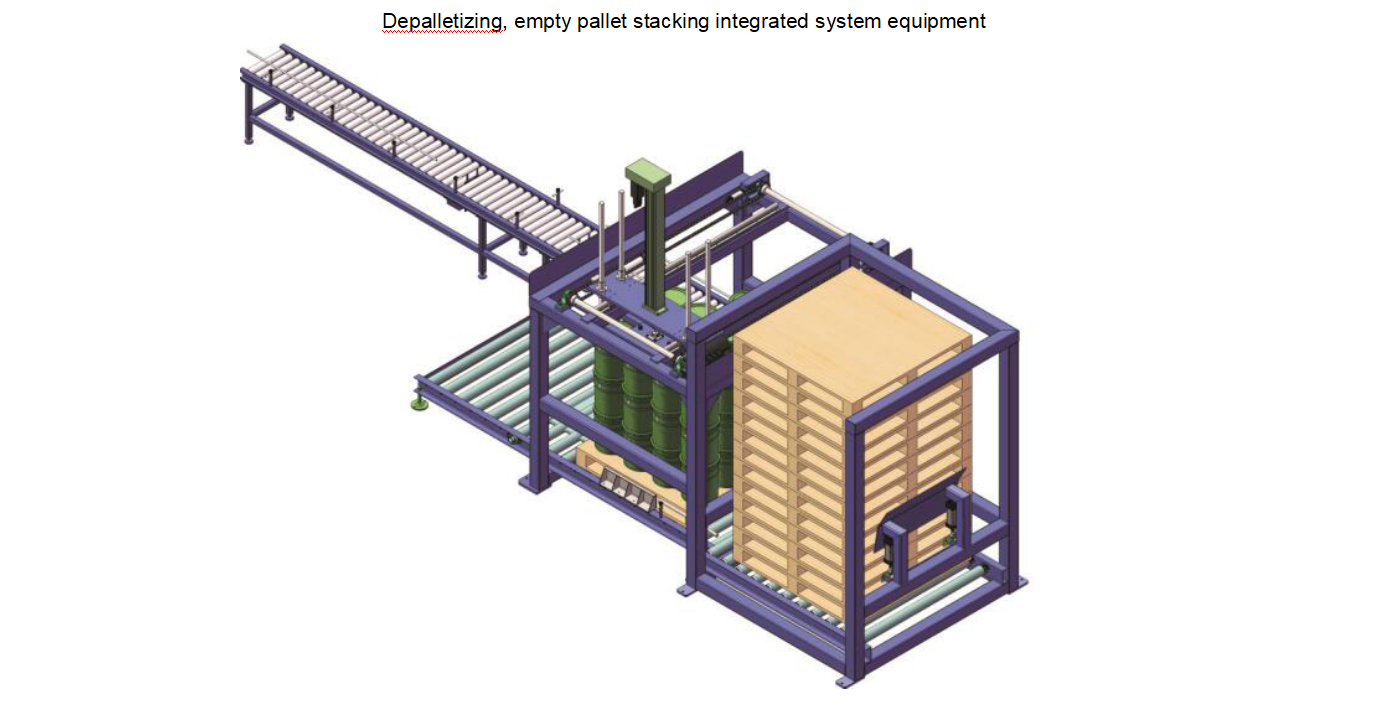

The palletizer is to put the cartons already packed into the container on the pallets and pallets (wood, plastic) according to a certain arrangement, and stack them automatically. It can be stacked in multiple layers and then pushed out to facilitate the forklift to transport to the warehouse for storage. This equipment adopts PLC+touch screen control to realize intelligent operation management, simple and easy to master. Can greatly reduce labor and reduce labor intensity. The palletizer is a device that automatically stacks the bags, cartons or other packaging materials from the conveyor into a stack according to the working method required by the customer's process, and transports the stacked materials.

The automatic palletizer is a high-tech product integrating machinery and electricity. The middle and low-position palletizer can meet the production needs of medium and low output. According to the required marshalling method and number of layers, the palletizing of various products such as bags, plastic blocks, boxes, etc. can be completed. The optimized design makes the stack shape tight and neat.

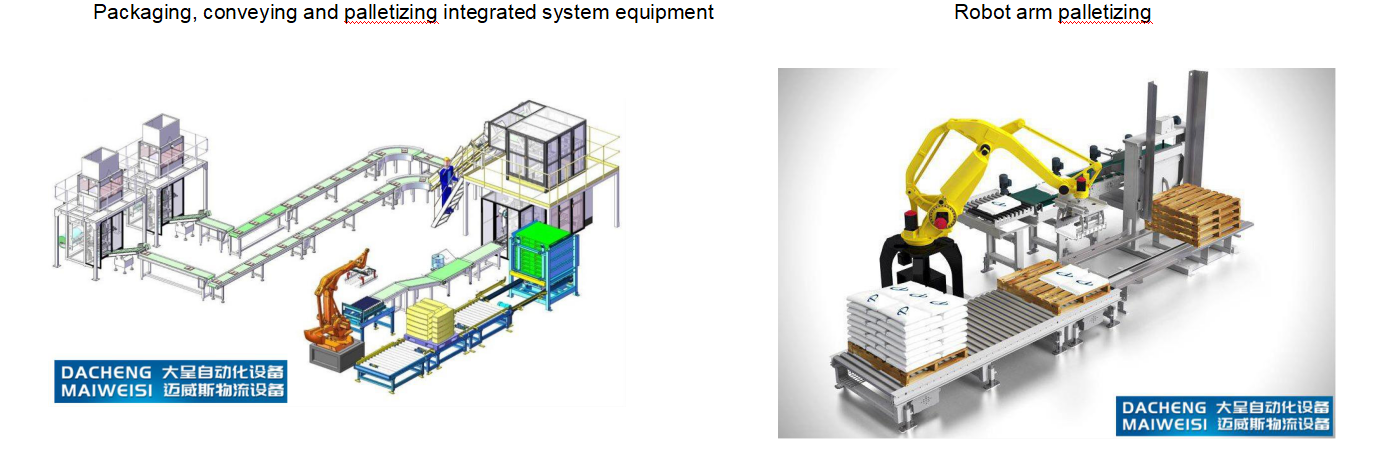

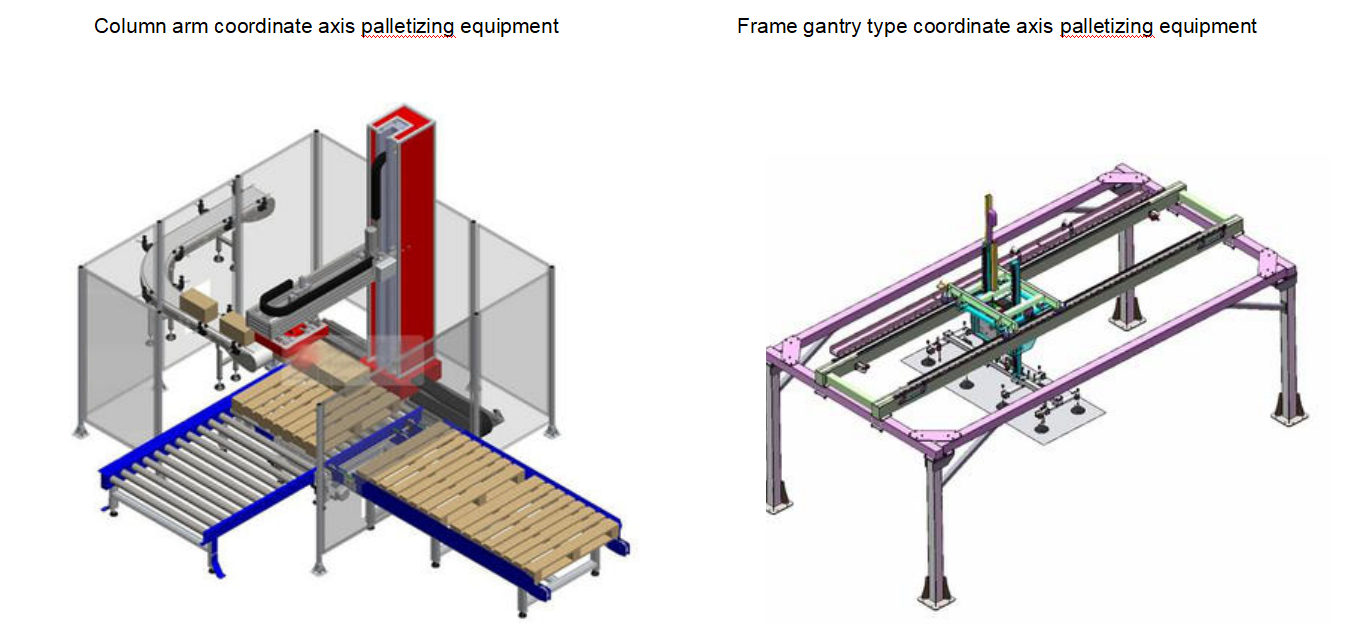

Automatic palletizers are divided into two types according to the level of intelligence: robot palletizers and mechanical palletizers. Mechanical palletizers can be divided into: gantry palletizers, column palletizers, and robotic arm palletizers.

According to the industry, automatic palletizers are divided into: food and beverage industry palletizers, cement automatic loading palletizers, industrial products palletizers, etc.

Product Features

The middle and low position palletizers are mainly composed of flattening conveyors, slow-stop conveyors, indexing conveyors, pallet bins, pallet conveyors, marshalling machines, bag pushing devices, palletizing devices, and pallet conveyors. The structural design is optimized, and the action is stable and reliable. The palletizing process is completely automatic, without manual intervention during normal operation, and has a wide range of applications.

1. The low-position box takes up less space and has a large production capacity;

2. The whole machine is controlled by PLC, fully automatic operation;

3. Adapt to a variety of stack types and bottle types, easy to adjust;

4. Multiple safety protections, which can be controlled by touch screen;

5. High-quality conveyor chain is used for segmented transmission, and the output section can be lengthened arbitrarily;

6. Motor, cylinder transmission and control all adopt imported brand-name components;

7. It is especially suitable for products packed with heat shrinkable film.

Control System

The main control components, including programmable controllers, variable frequency speed controllers, proximity switches, button switches and terminal blocks, are all made of first-class products to ensure the reliability and long life of the system hardware. The combination of high-quality hardware and specialized control software designed by experts realizes a high degree of automation of the system. The perfect safety interlocking mechanism can protect the equipment and operators. The graphic display touch screen makes the palletizer easy to operate, easy to diagnose faults, and convenient for overhaul and maintenance.

The robot palletizer can be integrated in any production line to provide intelligence, robotization, and networking for the production site. It can realize the palletizing logistics of a variety of operations in the beer, beverage and food industries. It is widely used in cartons, plastic boxes, and bottles. Types, bags, barrels, film-packaged products and filling products, etc. It is matched with three-in-one filling line, etc., to palletize all kinds of bottles, cans and bags. The automatic operation of the palletizer is divided into the steps of automatic loading, turning, sorting, stacking, shifting, lifting, loading, unloading, and unloading.

Technical Parameters

Work rate | 380V、50HZ、10KW |

Air pressure | 6 kg/cm2 |

Pallet scope of application | L:1600mm W:1600mm 内 |

Total height of stacking workpiece | 1600mm 内 |

If you need us to provide you with technical support services or purchase our equipment, you can obtain the information you need through the following contact methods:

v Tel:021-57805016/18717947953 Fax:021-57801828 E-mail:sh_dacheng@163.com